Hot Tapping and Line Stopping

Overview:

Hot tapping and line stopping, also known as pressure tapping or under-pressure drilling, is a specialized method used in various industries to create a connection to an existing pressurized pipeline or vessel without shutting down the system. This process is crucial for maintenance, repairs, modifications, and system expansion while minimizing downtime and ensuring continuous operation. In this overview, we will delve into the hot tapping process, its importance, and key considerations.

Importance of Hot Tapping

Hot tapping is a critical technique with several advantages:

- Minimized Downtime: Hot tapping enables repairs and modifications without the need to shut down the entire system, reducing costly downtime and production losses.

- Cost-Effective: The cost savings associated with hot tapping are substantial, as it eliminates the expenses related to system shutdowns and restarts.

- Reduced Environmental Impact: By avoiding system shutdowns, hot tapping consequently helps minimize environmental risks, such as spills and emissions, which are typically associated with depressurization.

The Hot Tapping Process

The hot tapping process involves several carefully executed steps:

Planning and Risk Assessment:

-

- Identify the need for hot tapping and conduct a thorough risk assessment.

- Determine the location and specifications of the tap, including size and material compatibility.

Equipment Preparation:

-

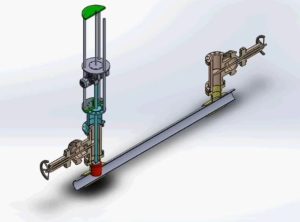

- Assemble specialized hot tapping equipment, including a tapping machine, cutter, and tapping valve.

- Ensure that all equipment is in optimal condition and meets safety standards.

Site Preparation:

-

- Set up a safe work area around the pipeline or vessel.

- Implement safety measures, including fire protection and gas detection systems.

Drilling:

-

- Drill a hole into the live pipeline or vessel using the tapping machine and cutter while maintaining system pressure.

- Capture any released materials, such as shavings or fluids, using containment devices.

Installing the Tapping Valve:

-

- Secure the tapping valve onto the newly created hole.

- Ensure proper sealing and leak prevention.

Pressure Test:

-

- Conduct a pressure test to verify the integrity of the tapping valve and the new connection.

- Monitor for any leaks or irregularities.

Connection and Operation:

-

- Attach the required equipment or piping to the tapping valve.

- Open the valve to establish a connection with the live system.

- Perform the necessary maintenance, repair, or modification tasks.

Closing and Sealing:

-

- After completing the required work, close and seal the tapping valve securely.

- Ensure no residual pressure or leaks exist.

Continual Monitoring:

-

- Continuously monitor the hot tapped connection for any signs of leaks or pressure fluctuations.

- Conduct regular inspections to ensure long-term integrity.

Hot tapping is a valuable process that allows industries to maintain, repair, or expand their systems without costly shutdowns. It requires careful planning, specialized equipment, and a commitment to safety to execute successfully. When done correctly, hot tapping ensures minimal downtime, cost savings, and reduced environmental impact, making it an essential technique in various industrial applications.