Blog

Pigging – Pipeline Integrity: Importance of Pigging.

Pipeline Integrity: Importance of Pigging.

Maintaining the integrity of pipelines is crucial for industries such as oil and gas, petroleum, and even water transportation. Any disruption or failure in these vital systems can lead to significant consequences, including environmental damage, financial losses, and public safety risks. To mitigate these risks, the practice of pigging has emerged as a vital technique to ensure the ongoing integrity of pipelines. In this blog, we will delve into the importance of pigging and its role in maintaining pipeline integrity.

Understanding Pigging:

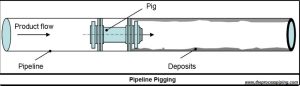

Pigging refers to the process of using pipeline inspection gauges, commonly known as “pigs,” to clean, inspect, and maintain pipelines. These pigs are typically cylindrical or spherical devices that are inserted into the pipeline and propelled by the flow of the product being transported. They can be equipped with various tools and sensors, depending on the specific purpose of the pigging operation.

Importance of Pigging for Pipeline Integrity:

1. Cleaning and Debris Removal:

Over time, pipelines can accumulate debris, sediment, and other unwanted substances that hinder the smooth flow of products. These obstructions not only reduce the pipeline’s efficiency but also increase the risk of corrosion and damage. Pigging plays a crucial role in cleaning pipelines by removing debris, sludge, scale, and other deposits. By maintaining a clean interior, pigging ensures optimal flow and reduces the chances of blockages or flow restrictions that could compromise pipeline integrity.

2. Inspection and Maintenance:

Pipeline integrity relies on regular inspections to identify and address potential issues promptly. Pigs equipped with advanced sensors can provide valuable data about the condition of the pipeline’s interior, detecting corrosion, cracks, leaks, and other forms of damage. By identifying these problems early on, maintenance crews can take corrective measures, such as repairs or replacement, to prevent further deterioration and potential failures. Regular pigging allows for proactive maintenance, reducing the risk of costly and disruptive incidents.

3. Preventing Corrosion:

Corrosion is one of the major threats to pipeline integrity. Pigging can help prevent corrosion by removing moisture, sediment, and corrosive substances that accumulate within the pipeline. Additionally, pigs can apply corrosion inhibitors or coatings to protect the pipeline’s interior surfaces. By regularly pigging the pipeline, operators can mitigate corrosion risks and extend the lifespan of the infrastructure.

4. Flow Assurance:

In pipelines transporting products such as crude oil or natural gas, flow assurance is critical to maintain operational efficiency. Pigging can help ensure flow assurance by managing issues like hydrate formation, wax deposition, and scale build-up. Specialized pigs, known as “smart pigs,” can monitor the flow characteristics, detect flow disruptions, and identify potential flow assurance challenges. By addressing these issues promptly, pigging ensures uninterrupted product flow and minimizes production losses.

5. Regulatory Compliance:

Pipeline operators are subject to strict regulatory requirements and standards to safeguard public safety and protect the environment. Regular pigging is often a mandatory component of integrity management programs, helping operators comply with regulations and industry standards. By demonstrating a commitment to pipeline integrity through pigging practices, operators can maintain public trust and fulfill their legal obligations.

Contact us: info@corepipe.co.za or visit our website to learn more www.corepipe.co.za